SILICONE AS A MATERIAL

Silicone rubber has many great qualities which makes it a versatile material for different applications. It has a great heat and frost resistance, wide hardness range, and it is also resistant to oils and chemicals. We have produced silicone products for over 40 years.

Wide hardness range

The hardness range of silicone is wide: 20–80 ShA. The higher the hardness rating, the harder the product will be. The softest materials (20 ShA) are used, for example, for sealing enclosures where no high compression is formed.

ShA

20 80

Wide operating temperature range

Silicone rubber has a very wide operating temperature range. Regular silicone grades retain their properties in temperatures between -50 °C and +200 °C. Special grades are resistant to temperatures as low as -90 °C. With additives, heat resistance can be increased to up to +300 °C.

Special grades are resistant to

temperatures as low as -90 °C.

Regular grades are resistant

from -50 °C to +200 °C.

With additives, heat resistance

can be up to +300 °C.

Several colours

Silicone rubber is easy to dye. Colours are silicone-based, and there are several colours available.

Durable in different conditions

Some silicone rubber grades are resistant to oil and chemicals. Special silicones are resistant to mild acids and alkalis with certain limitations. Silicone products preserve their colour and elasticity even in strong sunlight, because they have a good resistance to ozone and UV light.

Flame resistant silicone rubbers include grades with different classifications. Flame resistant silicones with especially high classification do not release poisonous gases. Ceramic powder will form on their surface during burning, protecting the rubber from being completely destroyed. These silicone rubber elements are used, for example, in underground railways.

Silicone that conducts electricity

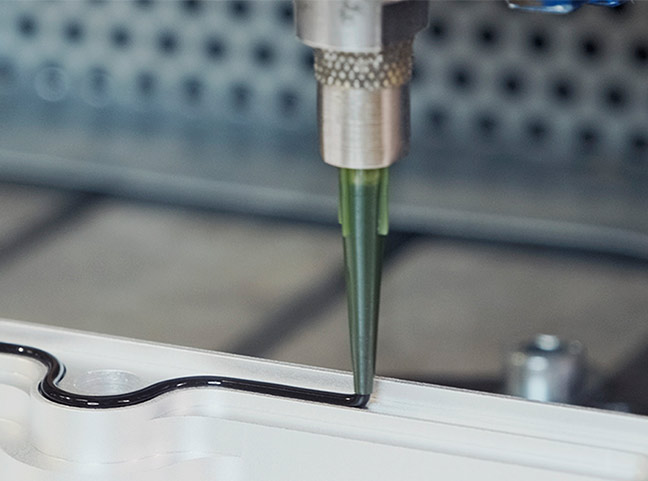

Some silicone grades also conduct electricity. Conducting silicone is used with the FIP sealing technology for interference protection of enclosures.

FDA and BfR approvals

Silicone rubber products have FDA and BfR approvals. These products can be used, for example, in contact with skin and cooking or in food production equipment. Silicone rubber is biologically inert.